The compressor is the component at the heart of a refrigerant circuit based on the so called “vapour compression cycle”. This thermodynamic cycle exploits the evaporation of a refrigerant inside a closed loop piping circuit. Specifically, evaporation occurs in a heat exchanger called the evaporator, which absorbs energy from the surrounding air; this is then delivered to the food storage compartment or air-conditioned space by natural or fan-forced convection.

The same also applies when using water as the medium, which is pumped through the heat exchanger and then flows into the storage tank for use by the terminal units. Once having evaporated, the refrigerant can no longer absorb considerable amounts of energy, and consequently it needs to be returned to the liquid state by condensation. The problem thus arises of having an environment that’s “cold” enough to absorb energy from the refrigerant, which naturally cannot be the same compartment or space that’s just been cooled.

The compressor is then used to compress the refrigerant to a pressure that’s higher than in the evaporator (up to 8-10 times!) so that the condensation process can take place at a temperature that’s compatible with a readily available “cold” source, typically the outside air.

Condensation thus occurs at a high temperature (usually 35-55°C) inside a heat exchanger where the two fluids are outside air and refrigerant. The latter condenses and returns to the liquid state, while the outside air will be heated.

The liquid refrigerant is still at high pressure when it leaves the condenser. An expansion device is thus needed to expand the liquid refrigerant and reduce its pressure to the value at which evaporation occurs. The refrigerant has now returned to its initial state (liquid at low pressure and temperature) and can once again absorb energy from the air or water.

Therefore, the compressor has the function of circulating refrigerant inside the circuit, drawing it in as a gas from the evaporator and then compressing it and delivering it at higher pressure to the condenser. It provides volumetric compression, i.e. a progressive reduction in volume, using rotating or reciprocating systems. This mechanical work implies a significant increase in the temperature of the gas (at times above 100°C) as well as power consumption. Compressor power consumption depends on the difference between the two operating pressures. The refrigerant entering the compressor must be in the gaseous state, as liquids are notoriously incompressible. The compressor starts working when the unit needs to provide cooling, and is usually activated via temperature control systems.

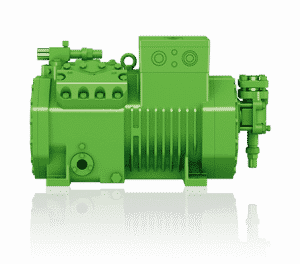

The reciprocating compressor uses piston to compressor the refrigerant driven by a crankshaft in a straight line back and forth motion. This rotary motion is achieved by the use of an electric motor and the construction is quite similar to that of an automobile engine.

The piston moves up and down inside a cylinder. Vapor from the suction line is moved through the intake valve as the piston move downward. As the piston moves upward, it compresses the vapor refrigerant which is then pushed through the exhaust valve into the condenser. The compressor may has more than one cylinder which is also known as multicylinder compressor. The common ones are the two-cylinder, four-cylinder and eight-cylinder compressors.

The rotary compressor can be divided into two types. One has blades or vanes that rotate with the shaft. The other type has the blade which remains stationary and is part of the compressor housing assembly. In both types, the vapor from the suction line is drawn into the cylinder through the suction port.

As the blade rotates, trapped vapor in the space ahead of the blade is compressed into high pressure gas after which it is discharged to the condenser through the exhaust port. The number of blades can range from two to eight in a single system.

Centrifugal compressor is usually used in large capacity refrigerating system. In this compressor, the vapor is moved in a circular motion known as centrifugal force. An impeller which is a disk with radial blades spins rapidly inside this housing causing the gas to gain velocity.

A diffuser converts this energy into pressure energy and is then discharged into the condenser. The pumping efficiency increases with speed, hence this type of compressors are designed to operate at high speed. The main advantage of centrifugal compressor is that there are no valves, pistons or cylinders. The wearing parts that need attention are the main bearings.

“I just thought I would share some feedback with you on this very hot day. In the past, our air conditioning has always struggled badly on these hot days.The guys out the front (with glass windows) would be sweating and they would turn the air right down. The people in the back of the office would need to bring jumpers and cardigans to work on a day like this. BUT NOW – AFTER YOUR TECHNICIAN WAS HERE LAST MONTH. It’s fantastic. We have been in this building for 10 years and the air conditioning has never worked better!! So thank you to everyone there for making that happen for us. We are all very happy and have been mostly unaware that it’s even a hot day out there. We love it!!”

“Your professionalism, quality, honesty, and delivery timeframes were outstanding given you were under an extremely tight schedule to get the project completed. I was especially impressed with your effort to accommodate any additions to the original scope, including the client's request to refurbish the entire kitchen two weeks prior to Christmas. I have no hesitation in recommending you and Coles Refrigeration & Air Conditioning to future clients and trust we will continue to further strengthen the relationship between our companies.”

“Coles have been responsible for the provision, installation and servicing of all our beverage and catering equipment, air conditioning & general refrigeration. I have conducted business with Coles since 1994. I have no hesitation in recommending Coles Refrigeration & Air Conditioning to prospective clients.”

“We were impressed by the excellent sales advise, design, installation and after sales service we received. All equipment restoration was carried out professionally keeping costs to a minimum. Coles Refrigeration & Air Conditioning ensured that our budget was met and that we received the best available equipment within that budget. For future requirement, we will not hesitate to involve Coles Refrigeration & Air Conditioning. Thank you for the professional input and service!”

“Thank you for the excellent work produced by your staff during the fit out of our new kitchen. The stainless steel exhaust and benchwork are second to none. Our cool room, pantry and freezer are working beautifully and the shelving and the layouts are exactly to our requirements. I will always be available to be contacted to recommend the work you and your staff did on our new kitchen.”

“Throughout all the stages of development and construction, I always found the staff from Coles to be highly professional and diligent in their works. Cole's tradesmen who carried out the works at our site were always helpful and met our stringent OH&S requirements. The buildings that were refurbished present various challenges with timeframes and meeting relevant codes and standards. With Cole's help, we were able to meet and exceed all expectations. I have no hesitation in recommending Coles Refrigeration for any future works in which they tender.”

“Mitchel Cousins has presented at two workshops held by the Energy Hunter team, helping businesses gain an understanding of real life ways to improve performance, reliability and cost savings of plant and equipment. Mitchell displayed high level of knowledge in both his specific industry, as well as energy efficiency. It was a pleasure working with Mitchell and I would happily do so again.”

“I was on site this morning at 47 Darby Street for the RMS Fitout project, and the foreman was heaping a fair bit of praise on you guys for the quality and speed of work! Thanks for helping us out on this one.”

Unit 1 / 3 Concord Street Boolaroo NSW 2284

Phone: (02) 4957 0221

Fax: (02) 4956 1616